CONTROL, MEASURE, HYDRO TEST

- You will be able to measure internal or external misalignment using a Hi-Lo measurer. L’AWS determine the convex and concave thickness and tolerances of the weld bead. Our vernier gauge will measure chamfer angles. The Bridgecam gauge or the ajustable fillet will be very useful for measuring weld bead and holes or checking alignment. The V-Wacit will allow you to control quickly and easily four essential measures : depth, comparison and amount of porosity and height of the weld bead. Other gauges remain at your disposal ( NF EN-970, fillet welding gauge, gap gauge, STFWG, pipe pit gage, taper gage…)

- We offer you a wide range from the simple kit to the most complete case.

- Reliably and quickly check your anti-corrosion coatings with tension will not be a problem thanks to Holiday detecto isotest 4S Elmed. The starter kit is composed of a controller, a battery, a charger, a grounding cable, a carrying bag, a user manual and a certificate calibration.

- Many accessories are available: springs of all sizes (spring or spiral electrodes), c grounding collar of special conductive rubber, insulated extension bars, insulared handles, electrodes, brass or rubber flat brushes (with or without angular adjustment), rake or brush electrodes, semicircular brushes…

- DEWITT, partner for decades of ERFI FRANCE, s a manufacturer renowned for the reliability, precision and quality of its pressure recorders (PSI or bar) and temperatures. Its range of Pressure temperature recorders offers a wide range of liquid pressure recording (water, oil…) or gas (air, various gases…). Manometric scales will allow you to simply calibrate gauges to a pressure of 20 000 PSI.

- Find also a complete range of manual test pumps from 30 to 1000 bars or pneumatic from 0 to 4 200 / 60 000 (with or without tank, with or without recorder…).

- According to the models (HP140, UX60, HP300, HP220, HP500, HP32/12, HP32/8 ), the pumps are usable either for pressures up to 630 or 1000 bars. The safety valve is part of the basic equipment. A pressure gauge connection G 1/2 is installed at the side of repression.

- Portable high pressure test pumps (RPS ) delivered with a direct supply or a tank, equipped as standard with a stainless steel pressure gauge class 1 (Ø4″), and a Class 1 mechanical recorder. Pneumatic inlet supply(maxi. 7 bars).

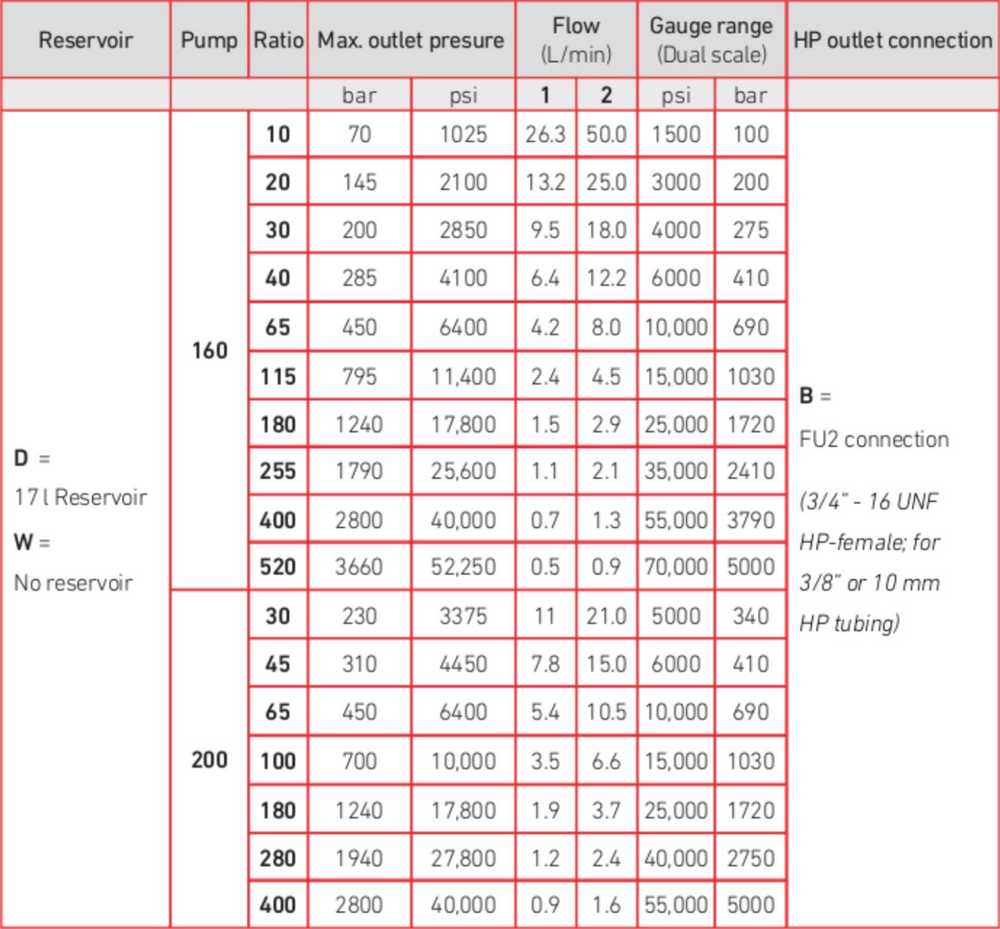

- Ideal for on-site pipeline testing in complete safety, thanks to its maneuverability and light weight. The range includes 10 models (table below) for events from 1 to 3650 bars in single or double action piston. The test fluid may be water, oil or an emulsion of both. The pump body is made of bronze, the piston, tubbing, valve and cradle are made of stainless steel.